A new issue of Cite is currently at the press. Subscribe or join now to get your copy. For the last few days, I have been conducting press checks with graphic designers. I find the process so fascinating I would like to share some pictures and basic explanations of how offset printing works. As the sole full-time staff person with Cite, my understanding of production has become more intimate, though I don't know all the terms and am more lay than expert.

After the graphic designers send the final InDesign files to the printer and I approve final changes to proofs, a special printer is used to etch aluminum sheets. I love the shining material, the glint of all our hard work. The etching is too subtle to detect by touch. Back in 1999, when I was an editorial intern with Carus Publishing, the plates for the books I worked on were made using negatives that were exposed on the metal. We would check "blueline" proofs made from the same negatives but on paper.

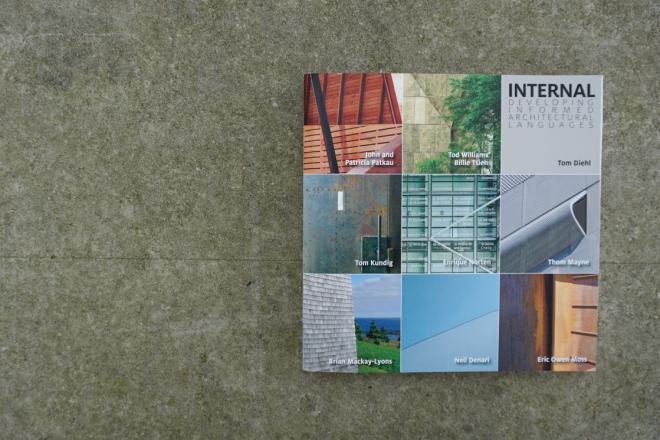

Heidelberg press.

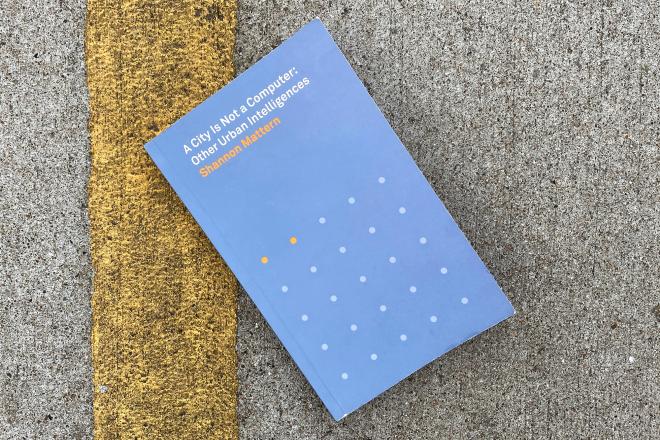

A press worker adding yellow ink to the press.

Printed sheet emerges from end of printer.

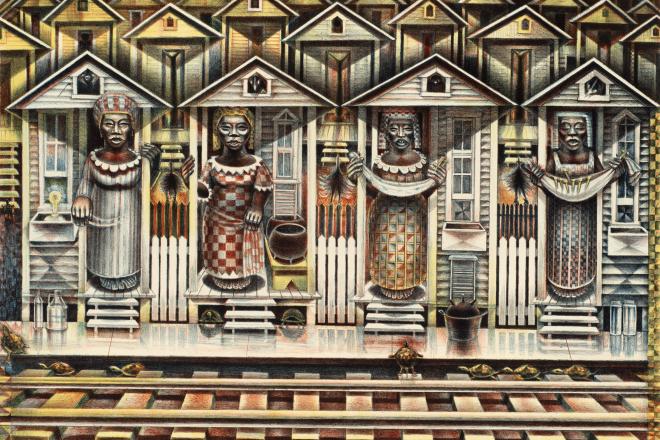

Printed sheets are reviewed at a lighted table.

The aluminum plates are then mounted in this giant Heidelberg press.

The sheets of paper move through the press. Cite now uses a four-color process, so the paper moves through four stations. At each one, there is a roller that applies ink to another roller wrapped with the aluminum plate. Then water washes off the excess ink and the image is transferred from the plate to a "blanket" roller. That blanket transfers the image to the paper.

At press checks, we look at the printed sheet on a lighted table. All those buttons along the bottom allow the press workers to adjust how much ink of each color is used.

Then the sheets go to the binder. From the binder it goes to the mail house. Then coffee tables, bathrooms, bookshelves, trash, recycling, libraries.